These implants minimise the need for bone grafting techniques and this means:

Designed with a micro-spiral to reduce vertical crestal bone resorption. Improves load distribution and fatigue strength. The design allows for higher initial stability values due to the osteotome effect generated during placement. Platform change is ensured by the machined 0.4 mm bevel, which creates a biological width that helps preserve bone levels.

The double-entry spiral allows for easy and continuous implant insertion. Active, self-tapping threads that increase in the apical direction gradually condense the bone, resulting in high initial stability coefficients in all bone densities.

Its helical self-tapping threads allow axial condensation of the bone, achieving a gradual osteotome effect.

The double internal hexagon allows for quick and tight insertion of the prosthetic components, specifically manufactured for this connection. Its 22° cone closure eliminates the possibility of bacterial leakage, making it suitable for low bone levels.

MPI has designed a machined surface in the crown area of the implant to be able to react to bacterial colonisation in the early stages.

The MPI Short® has a double surface treatment, which generates macro and micro-roughness, resulting in optimal roughness for fast and durable osseointegration.

The grade IV titanium used for MPI Short® implants is cold-formed. This treatment of the material improves its hardness by 20%, thus increasing the implant’s resistance to higher insertion torques. Material of German or Swiss origin.

In this type of implant, a correct restoration is a key factor. MPI offers a prosthetic solution specifically for this connection.

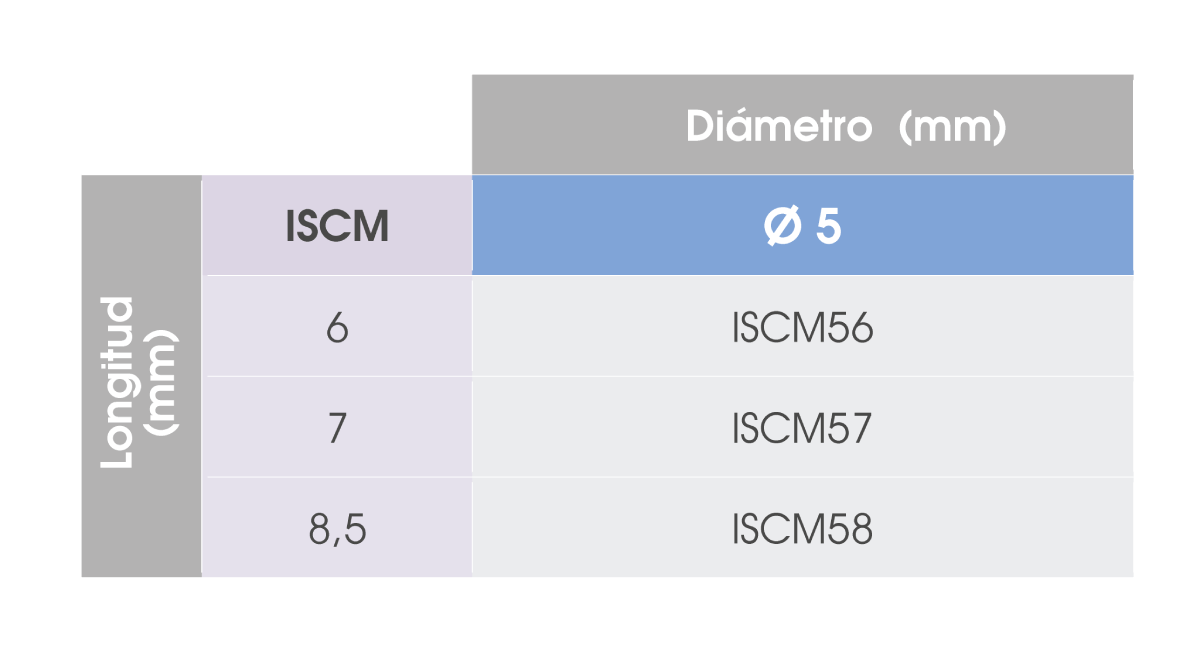

MPI Short® implants are available in three lengths to allow dental rehabilitation for different bone heights.